Digital Twins Catalyze the Lab’s Digital Revolution

The Internet of Things (IoT) has provided the pivotal launch point for today’s Digital Revolution. The network of sensor enabled technology is connecting the universe in unimaginable ways from SMART personal devices to automated technology powered by artificial intelligence to gather information from the surrounding environment. As use cases for this disruptive technology continue to evolve, a decades old concept gains new life, the ‘Digital Twin’.

The Internet of Things (IoT) has provided the pivotal launch point for today’s Digital Revolution. The network of sensor enabled technology is connecting the universe in unimaginable ways from SMART personal devices to automated technology powered by artificial intelligence to gather information from the surrounding environment. As use cases for this disruptive technology continue to evolve, a decades old concept gains new life, the ‘Digital Twin’.

The origins of the ‘Digital Twin’ date back as far as the 1960’s when NASA first pioneered the technology during space exploration missions when each voyaging spacecraft was exactly replicated in an earthbound version that was used for simulation and troubleshooting purposes without risk to the mission. The ‘Twin’ technology proved critical during the troubled Apollo 13 mission and helped NASA bring the astronauts home safely.1

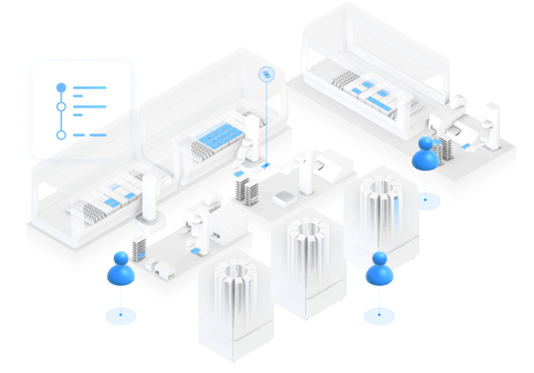

This revolutionary technology has evolved into a dynamic model of a physical system or entire laboratory operations to automate experimentation and accelerate scientific innovation with minimal barriers to ease of use, cost and risk.