RFID Functionality in Your LabWare LIMS

In our more than 200 person-years of experience with LabWare LIMS™, we’ve seen a lot of creative ways to derive business value from a LabWare system. Some are the easy wins, like instrument integration for improved automation or data visualization and dashboards for improved understanding of results. But we’re often surprised at the ways that our clients are NOT getting the most business value from their LabWare investment, in terms of missed opportunities for increased efficiency and data integrity.

In our more than 200 person-years of experience with LabWare LIMS™, we’ve seen a lot of creative ways to derive business value from a LabWare system. Some are the easy wins, like instrument integration for improved automation or data visualization and dashboards for improved understanding of results. But we’re often surprised at the ways that our clients are NOT getting the most business value from their LabWare investment, in terms of missed opportunities for increased efficiency and data integrity.

Sample tracking technology is one way to achieve that business value, and in our experience, the technology has been underused in LabWare applications. Many resist taking this path due to the customization that is necessary on both ends of the system, to enable the reader and LabWare to communicate with each other. The way sample tracking is implemented is to have the tag reader send files to a folder at specified intervals. Then LabWare LIMS can pick up the data in the folder and parse it to decide where to send it.

In this blog, we’ll share some examples of relatively easy ways to increase the functionality of your LabWare LIMS using one of the most common sample tracking methods, RFID tags.

Sample Tracking With RFID Labels

Many people often confuse the use of RFID tags and barcodes for sample tracking, so let’s talk through these differences first. Their concepts are similar, using an optical reader to extract data from a numerical or graphical code. RFID has some significant advantages, although cost is a drawback. How you plan to use the sample tracking method will determine which technology you should use.

Barcodes are relatively inexpensive because you can buy a printer and high-quality labels to make your own custom barcodes. Printing barcodes for samples give each sample a unique code that is read by a scanner, so that sample IDs cannot be mixed up or transposed due to human error. An advantage to the barcode technology is that it can be read by a scanner connected to your LabWare LIMS to import data into any text field that is selected prior to scanning. The scanner can also be used to populate a database table that can be queried and picked up for processing by a LabWare scheduler. Barcodes do have a few disadvantages, however. They are printed on paper and are subject to wear and tear, each must be scanned individually from a short distance (line of sight with scanner), and they have read-only functionality.

RFID tags are more expensive but are also able to be custom printed and encoded. RFID tags are both passive (read-only) and active (transmitting). RFID tags do not rely on line of sight and a batch of them can be read at the same time. Active RFID tags can help you locate a specific sample out of many. If you have the means to invest in an RFID system, their increased flexibility may offset the cost to a considerable extent.

RFID tags are scanned, just like barcodes, and the data is sent to a table for pickup by the LabWare scheduler. RFID readers, however, can gather information from all of the tags in range, even while they are moving. Placing more than one RFID reader in your laboratory can provide the direction of movement so that you would know when a certain sample was moved from one environment to another. Recent developments involving RFID labels and their integration with LabWare have yielded interesting examples of how sample tracking and data entry can be made easier.

EXAMPLE 1: RFID SOLUTION FOR STORAGE LOCATION TRACKING IN LABWARE

In a typical application, the Storage Location module in LabWare LIMS is used for environmental monitoring or disaster recovery planning. Storage Location Manager allows you to assign fields such as individual shelves in refrigerators or carts for transporting samples from one area to another. In this way, you can track the environmental conditions in which samples are stored, and know when a sample or batch has been compromised. If RFID functionality is paired with Storage Location Manager, you don’t have to print RFID labels for every sample to take advantage of the technology, one tag works for an entire batch.

→ Watch Webinar: Overcoming Critical LabWare Code Management Challenges

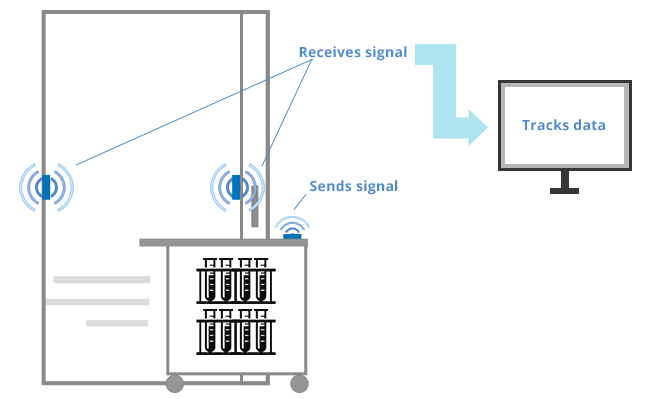

One of our clients affixed RFID labels to the top of moveable carts for transporting samples from one room to another; each of which have different environmental conditions (humidity, temperature). Our client wanted to track conditions of samples on the individual carts. To do this, some configuration was necessary. The reader had to be configured to populate a table in LabWare. This was done by someone familiar with the reader’s coding. The background scheduler in LabWare was configured to search the table at set intervals (in this case, every minute). Custom LIMS Basic code was written for LabWare to update the storage locations of the samples. Once the samples had been manually updated in Storage Location Manager to indicate that they were on a particular cart, the RFID tag on the cart could report, in real time, on what conditions each sample was subjected to as the cart moved throughout the facility.

An RFID reader was placed on each side of every doorway in every room that the carts would be moved to. That way, the direction of the cart movement could be determined. It was important to know the direction the samples were traveling because if there were only a single reader on one side of the door, you couldn’t be sure that the samples had actually been transferred into the new space. They could have just been parked near the opening.

Taking advantage of the sample tracking technology relieved lab staff of many manual updates that would normally need to be done. The RFID integration with LabWare Storage Location Manager eliminated human error and provided accurate, real-time recording of a sample’s duration at any one location. This proves very useful when, for example, someone is searching for a sample that may have just been moved or a report is needed to show how long a sample may have endured a particular environmental condition in the past.

→ Watch Webinar: LabWare LIMS Can Do That?

EXAMPLE 2: RFID LABELS FOR DATA INTEGRITY AND REDUCED HUMAN ERROR IN LABWARE

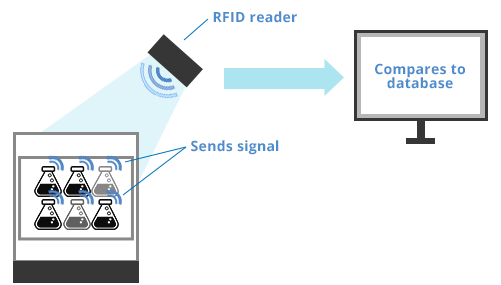

Another client had a workflow in which samples were collected and stored in a larger container. In theory, only samples of a particular project were stored together but, occasionally, samples from multiple projects could be stored in the same container if conditions permitted it. The client would sometimes find samples that were out of place, but they couldn’t be sure how often this had occurred without notice in the past.

As a solution, the client placed individual RFID labels on all samples by project. A step in the workflow was added to bulk scan the RFID labels of all samples in a container before they were put in storage. The container was placed under a reader that would accurately pick up all RFID labels of samples within, query the LabWare database, and display a message if any samples were read that did not belong together. Configuration of both the RFID reader and the LabWare database was again necessary, but by doing this, the client was able to immediately catch any mix ups.

Taking the time to configure a barcode or RFID reader to work with your LabWare LIMS system will save time, provide real time reporting on sample locations, ensure lab processes are followed, and reduce human error. These benefits have value to the wider organization outside the lab, as well

→ Request White Paper: Tips for Creating Highly Visual Workflows in LabWare